MILLING CUTTERS MACROZA

The cutting tool used in our WALL CHASERS is a milling cutter disc equipped with tungsten carbide teeth whose formula is exclusive MACROZA.

That is why MACROZA milling cutters are the most resistant on the market.

milling cutters MACROZA

The cutting tool used in our WALL CHASERS consists of a milling cutter disc equipped with tungsten carbide teeth whose formula is exclusive MACROZA.

For this reason, MACROZA milling cutters are the most resistant on the market.

MILLING CUTTERS FOR WALL CHASERS CUSTOM-DESIGNED

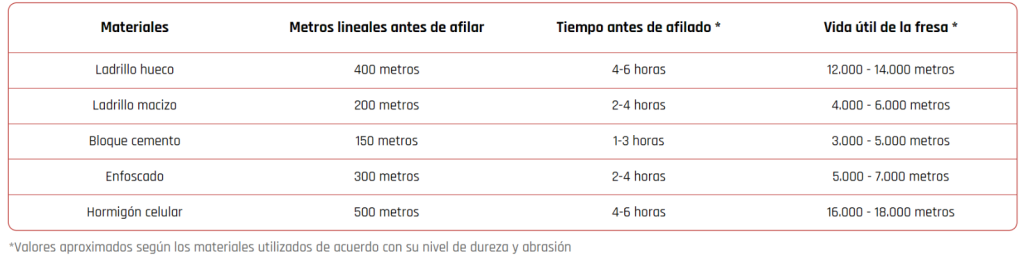

A whole range designed to allow you to work on almost any material, from the hardest and most abrasive materials such as solid bricks, cement blocks or plastered walls, to other standard materials of lower hardness where these milling cutters allow you to work for a longer period of time.

MILLING CUTTERS FOR PROFESSIONAL WALL CHASERS

RESHARPENABLE MILLING CUTTERS TUNGSTEN CARBIDE

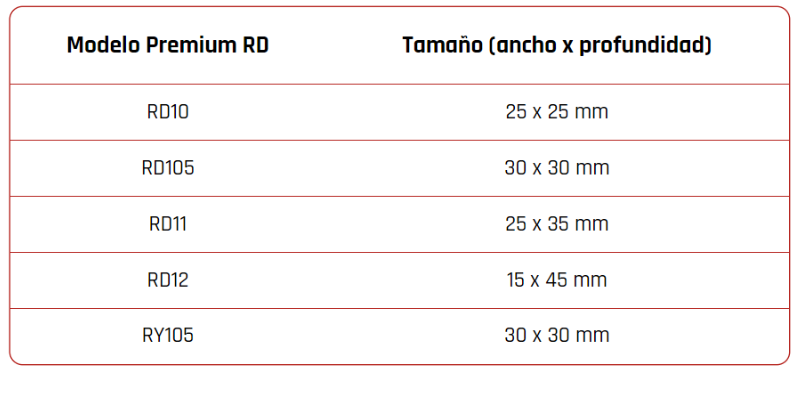

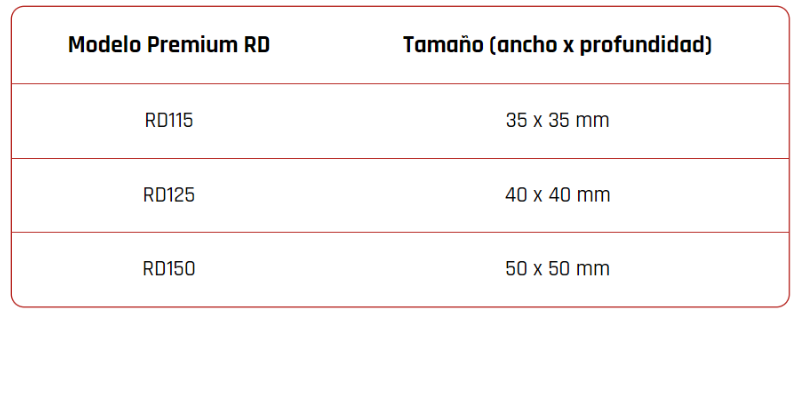

The MACROZA cutting element is a tungsten carbide regrindable milling cutter with an exclusive design for our wall chasers. There are 8 different types of milling cutters according to the required measurements and applications.

Our RD milling cutters range has been specially designed to work on harder materials such as solid bricks, cement blocks or plastered walls. Additionally, they can be used on standard materials of lower hardness where these milling cutters allow working longer and with a lower sharpening frequency, saving time of execution and milling cutter change.

LATEST MODEL RY105 MACROZA MILLING CUTTER

In addition to the RD series, we have designed a new milling cutter specially designed for aerated concrete and gypsum blocks. These materials are soft and abrasive, so they need a specific tool to cut without destroying the block or wearing the milling cutter too much. With the new RY 105 milling cutters we achieve:

- Maximum performance. Lifetime of up to 16,000 linear meters/milling cutter*.

- It hardly leaves a trace. Perfect channel by breaking only the necessary channel.

- It does not dull, as happens with the diamond blade when the material is heated during the work.

* Approximate values depending on material and work experience.

When working with cellular concrete or gypsum blocks, it is highly recommended to use a vacuum cleaner, since it is a material that generates more dust and debris.

To maintain the best performance and extend the life of these milling cutters, it is crucial to maintain them properly.

For this purpose, we have also designed a Sharpening Kit with which it is possible to leave the milling cutters in perfect condition and ready for chasing any material. Don’t miss the video!

specifications and features FOR MACROZA MILLING CUTTERS

MILLING CUTTERS FOR ALL OUR WALL CHASERS

MILLING CUTTERS EXCLUSIVELY FOR

LEARN HOW TO USE MACROZA MILLING CUTTERS

how to work WITH MACROZA MILLING CUTTERS

HOW TO DISASSEMBLE THE MILLING CUTTER?

To disassemble the milling cutter we will use the special wrench and the fixed wrench supplied with the MACROZA machine.

Hold the shaft by resting the fixed key in the housing of the milling cutter cover.

Loosen with the special wrench by hooking it on the bottom tooth and the fingernail on the opposite tooth.

Tap the special key once it is fastened.

HOW IS THE MILLING CUTTER MOUNTED?

The different milling cutters of the MACROZA wall chasers are specific to the MACROZA. Use only original MACROZA milling cutters.

Always when handling the milling cutter, the machine must be unplugged and the switch must be in the stop position.Before inserting the milling cutter it is very important to place the washer that is enclosed with it, which will make a perfect seat with the shaft and will facilitate the subsequent disassembly of the milling cutter.

The milling cutter is threaded onto the shaft by turning it counterclockwise with the teeth in the cutting position, as indicated by the arrow engraved on the milling cutter cover.

WOULD YOU LIKE TO TALK TO OUR TEAM?

Fill out the form below and let us know how we can help you. Whether to get your milling cutters or if you are a distributor, we will be happy to get back to you as soon as possible. Thank you very much!

C/ María Pedraza, Nº 3

28039 Madrid - Spain

+34 91 541 92 94

+34 608 969 404

Email

info@macroza.com

Monday to Thursday: 9am - 5pm

Friday: 9am - 3pm