Wall Chasers MACROZA

Latest technology incorporated. Wall Chasers unique milling cutters on the market that guarantee maximum performance and the best results.

Motor de 2800 W a 9.200 RPM, alto rendimiento para materiales de gran resistencia.

La rozadora de pared MACROZA con sistema de fresa más potente del mercado. De 2.800 W de potencia. La rozadora de los profesionales.

Modelo de rozadora versátil y ligera. La mejor opción relación coste-beneficio. Ideal para materiales de dureza media.

Advantages of Wall Chasers MACROZA

Speed and accuracy, significantly reduces costs

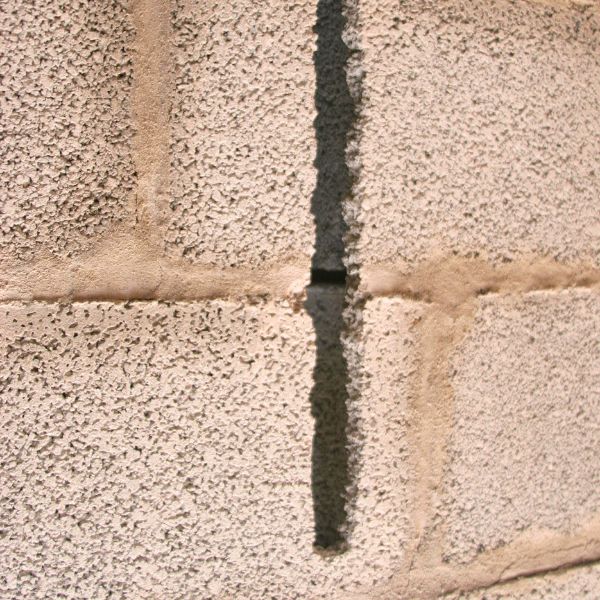

Opens chases clean and finished in a single pass without shredding

You will recover the investment of your wall chaser in a very short working time.

They go where others cannot and enable excellent results to be achieved

Delivers high performance in cement, concrete and stone

The user only has to guide the wall chaser without carrying its weight.

Discover our RANGE OF WALL CHASERS

Our entire product range incorporates the latest technology. Since 1956 we have been innovating and including new functionalities in every wall chaser we bring to the market.

Now with diamond discs

MACROZA D500

The D500 is the perfect machine for chasing chases in extremely hard and abrasive materials.

Works even on concrete, cement and stone.

Power and power in your hands.

MACROZA SC300 PRO

With 2800W of power, the SC300 PRO Wall Chasers can make straight and curved chases without any difficulty.

Opens channels up to 50×50 mm. in concrete, brick and plaster.

MACROZA M95

This wall chaser incorporates 2,400 W of power and is perfect for working on materials such as brick or light concrete.

It also has a light and versatile design that will allow you to work twice as fast.

MORE FEATURES OF OUR WALL CHASERS

Enjoy this demonstration video to see for yourself some of the benefits of our machines for making chases.

Latest technology, exclusive designs, milling cutters and diamond discs for better results. All combined in our wall chasers to offer you advantages over any other option.

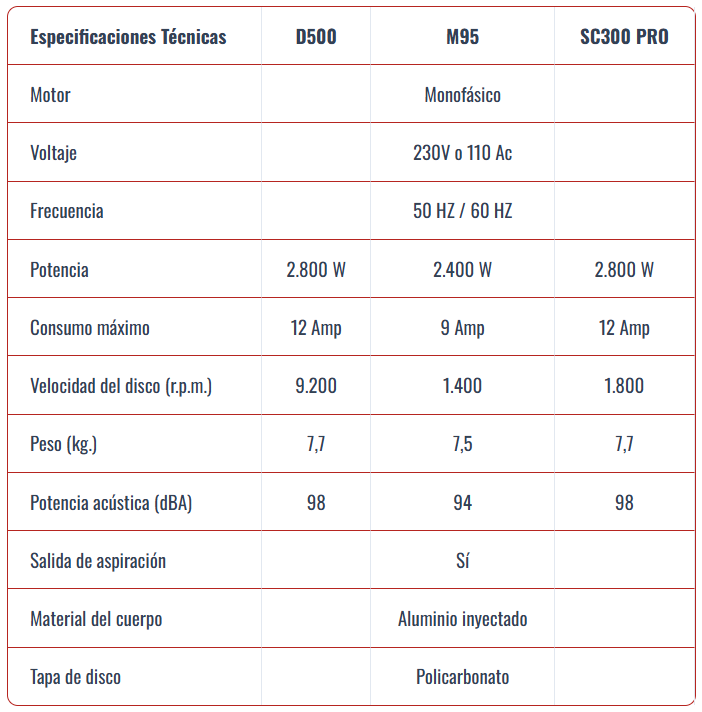

| Technical Specifications | D500 | M95 | SC300 PRO |

|---|---|---|---|

| Motor | Single-phase | ||

| Voltage | 230V or 110 Ac | ||

| Frequency | 50 HZ / 60 HZ | ||

| Power | 2.800 W | 2.400 W | 2.800 W |

| Maximum consumption | 12 Amp | 9 Amp | 12 Amp |

| Disc speed (r.p.m.) | 9.200 | 1.400 | 1.800 |

| Weight (kg.) | 7,7 | 7,5 | 7,7 |

| Sound power (dBA) | 98 | 94 | 98 |

| Suction outlet | Yes | ||

| Body material | Injected aluminum | ||

| Disc cover | Polycarbonate |

MVC30/1 VACUUM CLEANER of the Wall Chasers

Since 1956, we have been improving our products day by day.

Each of our machines has different features, carefully incorporated to achieve the best results chasing walls.

Choose the wall chaser that best suits your needs and contact us if you have any doubts.

We have a wide network of distributors so that you can purchase your products quickly and easily.

GET YOUR wall chaser macroza

Contact us and we will get back to you as soon as possible.

Receive detailed information about our products and our commercial network MACROZA, We are waiting for you!

LEARN HOW TO USE OUR WALL CHASERS

How to work with macroza

Learn how to use our unique Wall Chasers and enjoy better results saving time and money. More meters in less time!

Our technology is far ahead of any other product on the market, offering you a series of exclusive advantages that will allow you to work with wall grazing in a much more professional, comfortable and precise way.

Main advantages of Macroza over others wall chasers

More meters in less time

It is the fastest, reduces costs significantly. Compared to the traditional method of hammer and chisel, grinders and other machines from chases, the wall chasers MACROZA makes the work of opening chases in walls and partitions to embed electrical, water, heating, TV, air conditioning, etc. pipes exceptionally fast, easy and light. With MACROZA it takes only 15 seconds to open one meter of chase. The following table shows the production speed with MACROZA.

| Material | Manually | Diamond disc | With macro chuck |

|---|---|---|---|

| 1 Operator | |||

| Solid brick | 50 m / day | 150 m / day | 400 m / day |

| Hollow brick | 100 m / day | 300 m / day | 800 m / day |

| Cement block | 40 m / day | 200 m / day | 450 m / day |

* These values are approximate, depending on the hardness and degree of abrasion of the material.

The best cost-benefit ratio

You will recover your investment in a very short time. Being able to make more than 500 m of chase in one day, calculate the time it takes to amortize the cost of the wall chaser. Thanks to the benefits offered by MACROZA, you recover the initial cost of the machine in a short period of time.

Does not break, does not shatter

Opens chases clean in a single pass. Have you calculated the cost of wreckage when doing the chases by hand or with a jackhammer? With MACROZA you can make chases clean and perfect in a single pass. Compared to conventional methods of opening chases, with MACROZA you can save up to 80% in time and materials.

More from wall chasers MACROZA

Hardly makes any dust

Granulates the material avoiding the production of dust. The MACROZA Wall Chasers produce hardly any dust. The low speed at which the milling cutter works means that it does not polish the material when cutting, as the diamond disc does, but simply granulates it. The debris produced accumulates on the disc cover and is then deposited on the floor. Therefore, it does not require a vacuum cleaner, as other machines do. All our models incorporate the option of attaching a vacuum cleaner if you need to work in indoor environments.

Attaches itself to the wall

The weight of the machine is not supported by the operator. The unique design of the MACROZA machine causes it to lean against the wall when cutting, thus taking up part of the weight of the machine. That is why we say that its weight is not important because it is supported by the wall itself. With MACROZA you can work longer with less effort. To work, just push the machine once it has been nailed to the wall.

The most powerful on the market

Works in materials where other Wall Chasers cannot. The MACROZA wall chasers have the most powerful engines on the market, which allows them to work in materials that other chasing machines cannot, such as cement block, solid bricks and concrete. With the MACROZA machine you will be able to work on:

- Gypsum wall

- Cellular concrete

- Cement plaster

- Hollow brick

- Solid brick

- Cement block

- Concrete

With MACROZA you can cut all types of material including stone and reinforced concrete.

Built to last

Low maintenance of the machine. Our more than 50 years of experience have resulted in a machine with simple yet very robust mechanics, ideal for the hard and rigorous work of opening chases. There are only 3 basic cares to be done to the machine:

- Clean the dust machinewith compressed air at least twice a week.

- Perform a general overhaul of the machine every 100 working hours, with emphasis on the brushes and bearings.

- If you work with milling cutters, always keep them sharp. Otherwise , you will not cut the material but will hit it, transmitting the blows to the machine and causing damage to bearings, pinions and motor.

Increased safety

Exclusive design to avoid accidents. The unique design of the machine protects the operator from the cut-off wheel, unlike other machines such as radials. The disc cover encloses the disc to prevent accidents. The wall chasers MACROZA has double electrical insulation and complies with all electrical safety regulations.

Open all types of chases

It hardly leaves any finishing touches in the corners. The MACROZA Wall Chasers can open vertical, horizontal, oblique and close to the ground chases. The milling chasers also allow to make all kinds of curved chases, unlike the other machines on the market. It leaves only 1 cm of overhang in corners and ceilings thanks to the position of the discs located on one side of the machine, unlike other milling cutter disc machines.

Vacuuming of dust and debris

Dust and debris collection option. All our models can be connected to a vacuum cleaner if the job requires it. To do this we screw an aluminum tube into the cap of the Milling cutter, which is in turn connected to the vacuum cleaner. This is highly recommended for working in indoor or living spaces, or work environments that require minimizing dust and debris production as much as possible. If it is not necessary to use the vacuum cleaner, a protective cap, also made of aluminum, is screwed in place of the aluminum tube.

What do I have to do to start working with a Macroza wall chaser?

It is essential that the machine is properly gripped, as this is essential for the proper performance of the work. To do this we must follow the instructions in the instruction manual.

The photos below show the correct way to hold the machine.

To start the work, operate the switch with the discs rotating in the air to check the direction of rotation and positioning of the discs.

the discs should move forward. Lean the machine sideways on the wall and, swinging, insert the discs little by little into the wall. Hold the machine firmly to avoid initial vibrations.

How to make chases verticals?

The vertical chases are made from top to bottom. The right hand will be on the switch handle and the left hand on the disc housing.

The left hand is the guiding hand and the main effort. Once the discs are inserted into the wall, by pulling the machine with both hands at the same time, it will produce a straight channel.

It is very important that the machine is properly gripped. Guides on each side of the disc cover will indicate the cutting direction.

To open chases obliquely we will follow a process similar to that for opening vertical chases.

How to make chases horizontal?

The horizontal chases are made from right to left. The right hand will grasp the machine by the right side of the disc housing handle and push to the left.

The right arm will rest on the machine and push it from the bottom also to the left. The left hand will embrace the switch handle acting on it.

The following pictures show how to place the hands. It is very important that the machine is properly gripped.

How to make chases circulars?

MACROZA’s M90 and SC300PRO milling cutters are the only ones on the market capable of making curved chases. To do so, we will start from the traditional chases opening described above.

When performing chases both vertically and horizontally, a difference in displacement between one hand and the other rotates the machine, producing a curved chase.

The following photographs show the different postures that the hands must adopt in the successive opening phases of a curved chase.

How to perform chases close to the ground?

The horizontal chases near the ground are made from left to right.

The right hand will grasp the machine by the rear handle and the left hand will grasp the left side of the disc housing handle and push to the right.

Thanks to the unique design of the machine MACROZA, the user will be able to work in places that are more difficult to access.

In the following photos we can see how chases is made close to the ground. It is very important that the machine is properly gripped.

How to make chases wider, manhole and switch boxes?

It is possible to make wider chases. To do this, we will make two parallel cuts side by side, obtaining twice the width.

It is also possible to build manhole and switch boxes. To do this we will first make a cut on each of the sides where the register box will go. Then remove the remaining center by moving the machine from one side to the other until it is emptied.

In the following pictures we see the correct position of the hands.

How to maintain the machine properly to ensure a longer service life?

We recommend that all maintenance work be carried out by a specialist at an Official Service Center MACROZA.

Always use original spare and replacement parts MACROZA to avoid risks to the user’s safety.

DAILY

If your wall chaser has a milling cutter

Check the state of sharpness of the teeth of the milling cutters approximately every hour of work. To do this, use the sharpness tester MACROZA. Replace or sharpen the milling cutter when it becomes dull.

The sharpening of the milling cutter will be done dry using the Sharpening kit MACROZA , specially designed for our milling cutters. Alternatively, a grinder with a silicon carbide 80 grit, Grade JK grinding stone may be used.

Machine cleaning

At the end of each working day, it is important to check the condition of the brushes and clean the machine of dust by blowing pressurized air through the grids if necessary.

PERIODICALLY

All wall chaser used professionally on a daily basis should be checked at least once a month.

Bearings

Check the clearance in the Milling cutter shaft bearings. At the slightest oscillation we recommend its replacement, otherwise it will cause serious damage to the mechanics of wall chaser.

Under normal conditions and due to the hardness of the work performed, it may be necessary to replace the bearings every month.

Brushes

Check through the side slots if the sparks produced by the brushes in the collector are higher than normal. Check their condition. If necessary, replace them. Never change only one wiper blade, always replace both at the same time.

It is not advisable to use up the brushes.

TOOL KIT MACROZA

In our eagerness to offer a quality service, we have developed a set of tools specially designed to open and repair our equipment in a comfortable, fast, efficient and safe way.

Each tool is tailor-made so that parts can be changed in a way that does not damage the machine as a whole.

This set of tools had been in use for many years in our own assembly plant and service centers. Now, we make it available to our network of official technical services in Spain and to our distributors and technical services abroad.

Feel free to ask us about our tool kit MACROZA.

For the rest of the components of the wall chaser there is no established maintenance period.

These will be replaced according to wear and tear.

MORE INFORMATION ABOUT OUR WALL CHASES CHASING MACHINES

Would you like to get your hands on a ROZADORA MACROZA?

Fill in the form and we will contact you as soon as possible. Thank you very much!

C/ María Pedraza, Nº 3

28039 Madrid - Spain

+34 91 541 92 94

+34 608 969 404

Email

info@macroza.com

Lunes a Jueves: 9am - 5pm

Viernes: 9am - 3pm